Our Roller Mixer is engineered to deliver superior mixing performance, ensuring perfectly blended coal powder for high-quality briquettes every time. With robust construction and cutting-edge technology, our Roller Mixer is the ideal choice for optimizing your coal briquetting process.

Capacity

Motor Power(kw)

| 型号 Model |

SM1000 | SM1200 | SM1500 | SM1800 |

| 产量 Capacity(t/h) |

1-2 | 2-3 | 3-5 | 5-8 |

| 功率 Motor Power(kw) |

5.5 | 5.5 | 7.5 | 15 |

Are you looking to enhance the efficiency and consistency of your coal briquetting production line? Our Roller Mixer is engineered to deliver superior mixing performance, ensuring perfectly blended coal powder for high-quality briquettes every time. With robust construction and cutting-edge technology, our Roller Mixer is the ideal choice for optimizing your coal briquetting process.

Why Choose Our Roller Mixer?

Exceptional Mixing Efficiency

Our Roller Mixer ensures uniform blending of coal powder, binders, and additives, creating a homogeneous mixture that is critical for producing durable, high-quality briquettes.

Robust and Durable Design

Built with high-grade materials and precision engineering, our mixer is designed to withstand the abrasive nature of coal, ensuring long-lasting performance with minimal downtime.

Energy-Saving Operation

Optimized for low energy consumption, our Roller Mixer reduces operational costs while maintaining high productivity, making it a cost-effective solution for your production line.

Easy Maintenance

With a user-friendly design and accessible components, maintenance is quick and hassle-free, minimizing interruptions to your production schedule.

Customizable Solutions

We offer tailored configurations to meet your specific production needs, including capacity adjustments and integration with existing briquetting equipment.

Consistent Output Quality

Advanced mixing technology guarantees a uniform mixture, resulting in briquettes with consistent density, strength, and combustion performance.

Safe and Reliable

Equipped with safety features such as emergency stop mechanisms and protective guards, our Roller Mixer ensures a secure working environment for your operators.

Provide regular maintenance plans and fast troubleshooting to address operational challenges.

Ensure the long-term availability of original spare parts to maintain stable equipment performance.

24/7 technical assistance via phone, email, or remote support to resolve issues promptly.

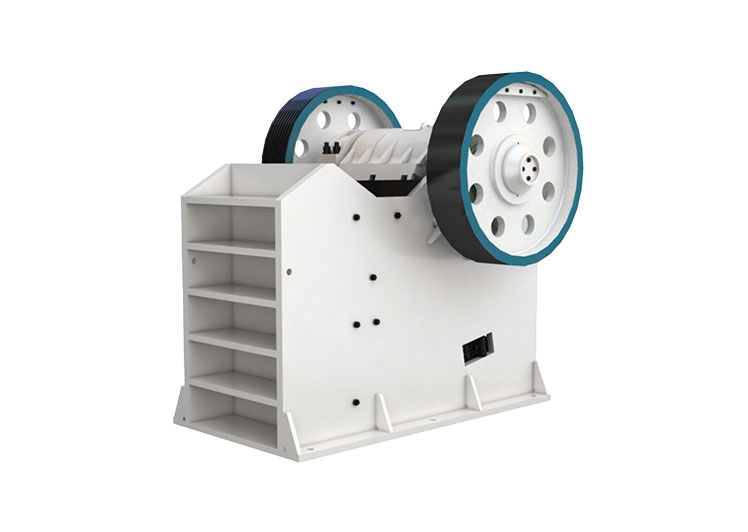

We provide a wide range of crushing machines, including jaw crushers, cone crushers, impact crushers, hammer crushers, and mobile crushing plants. Each type is designed for specific applications and materials.

Our machines are capable of processing various materials, including hard rock, ore, limestone, granite, basalt, recycled concrete, and more. They are suitable for mining, quarrying, and recycling operations.

The choice depends on factors like the type of material, required output size, production capacity, and operational conditions. Our team can help you select the best machine based on your specific requirements.

Yes, we offer a comprehensive range of spare parts and dedicated after-sales support to ensure your equipment operates smoothly throughout its lifespan.