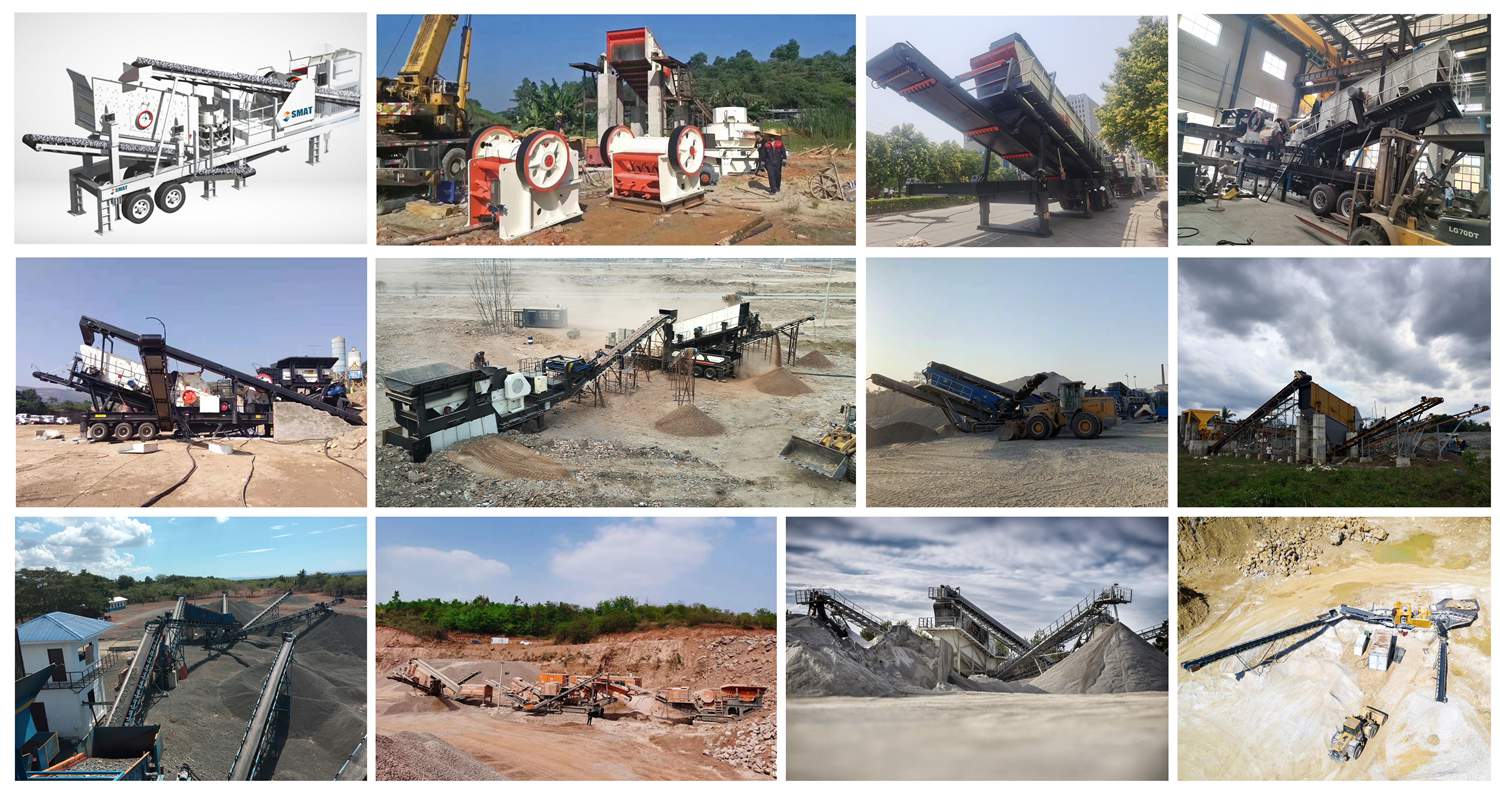

crushing plant is a facility designed to reduce large rocks or ores into smaller pieces for construction or industrial use. It typically includes primary, secondary, and tertiary crushers, along with screens and conveyors. Crushing plants are essential in mining, quarrying, and recycling operations, processing materials like granite, limestone, and concrete into desired sizes for further use.

SMAT is a leading global manufacturer of mining machinery and industrial equipment, specializing in the research, development, production and sales of mining crushing machinery, grinding machinery, mineral processing equipment, ball press equipment and generator sets. With efficient, durable and energy-saving equipment as its core competence

Primary/secondary crushers break blasted rock into marketable sizes, with equipment designed for rugged terrain and abrasive materials.

Crushers produce gravel, sand, and crushed stone for concrete/road bases, demanding high output and uniform particle sizing.

Crushing machines break rocks into sand-sized particles, while screening/washing equipment refines the material by removing impurities, ensuring clean, graded sand for construction use.

| Model | Size of Feeder Opening (mm) | Max. Feeding Size (mm) | Adjustment range (mm) | Processing Capacity (t/h) | Over all Dimension (mm) | Motor Power (kw) | Weight (t) |

| PE150×250 | 150×250 | 125 | 10-40 | 1-3 | 720×660×850 | 5.5 | 0.8 |

| PE200×300 | 200×300 | 180 | 15-50 | 2-6 | 910×750×990 | 7.5 | 1.2 |

| PE200×350 | 200×350 | 180 | 18-70 | 3-10 | 1000×870×990 | 11 | 1.5 |

| PE250×400 | 250×400 | 210 | 20-60 | 5-20 | 1300×1090×1270 | 15 | 2.8 |

| PE400×600 | 400×600 | 340 | 40-100 | 16-60 | 1730×1730×1630 | 30 | 7 |

| PE500×750 | 500×750 | 425 | 50-100 | 40-110 | 1980×2080×1870 | 55 | 12 |

| PE600×750 | 600×750 | 500 | 150-200 | 80-240 | 2070×2000×1920 | 55 | 15.8 |

| PE600×900 | 600×900 | 500 | 65-160 | 50-180 | 2190×2206×2300 | 55 | 17 |

| PE750×1060 | 750×1060 | 630 | 80-140 | 110-320 | 2660×2430×2800 | 110 | 29 |

| PE800×1060 | 800×1060 | 640 | 130-190 | 130-330 | 2710×2430×2800 | 110 | 29.8 |

| PE830×1060 | 830×1060 | 650 | 160-220 | 150-336 | 2740×2430×2800 | 110 | 30.7 |

| PE870×1060 | 870×1060 | 660 | 200-260 | 190-336 | 2810×2430×2800 | 110 | 31.5 |

| PE900×1060 | 900×1060 | 685 | 230-290 | 230-390 | 2870×2420×2940 | 110 | 33 |

| PE900×1200 | 900×1200 | 750 | 95-165 | 220-450 | 3380×2870×3330 | 110 | 52 |

| PE1000×1200 | 1000×1200 | 850 | 195-265 | 315-500 | 3480×2876×3330 | 110 | 55 |

| PE1200×1500 | 1200×1500 | 1020 | 150-350 | 400-800 | 4200×3300×3500 | 160-220 | 100.9 |

| PE1500×1800 | 1500×1800 | 1200 | 220-350 | 500-1000 | 5160×3660×4248 | 280-355 | 139 |

| PE1600×2100 | 1600×2100 | 1500 | 300-400 | 1300-2200 | 6210×4013×4716 | 350-380 | 150.6 |

| Model | Cavity | Max. Feeding size(mm) | Minimum Discharge size(mm) | Install power(kw) | Capacity(t/h) |

| SC100 | F1 | 150 | 10 | 90 | 45-135 |

| F2 | 90 | 10 | 90 | 43-118 | |

| F3 | 50 | 6 | 90 | 36-71 | |

| SC160 | F1 | 200 | 13 | 160 | 69-215 |

| F2 | 115 | 10 | 160 | 57-184 | |

| F3 | 75 | 8 | 160 | 63-126 | |

| SC250 | F1 | 215 | 16 | 250 | 116-396 |

| F2 | 140 | 13 | 250 | 97-328 | |

| F3 | 70 | 8 | 250 | 95-252 | |

| SC315 | F1 | 275 | 16 | 315 | 177-662 |

| F2 | 175 | 16 | 315 | 162-552 | |

| F3 | 85 | 13 | 315 | 195-401 | |

| SC560 | F1 | 300 | 22 | 560 | 448-1512 |

| F2 | 195 | 19 | 560 | 380-1373 | |

| F3 | 90 | 13 | 560 | 357-912 | |

| SC750 | F1 | 370 | 25 | 750 | 394-2181 |

| F2 | 300 | 19 | 750 | 342-2020 | |

| F3 | 230 | 16 | 750 | 267-1814 | |

| F4 | 120 | 13 | 750 | 248-1165 | |

| F5 | 85 | 10 | 750 | 185-1170 |

|

Model |

PF1007 |

PF1010 |

PF1210 |

PF1214 |

PF1315 |

PF1520 |

PF1820 |

|

Size of feeder opening (mm) |

400×730 |

400×1080 |

400×1080 |

400×1430 |

860×1520 |

830×2040 |

1260×2040 |

|

Rotor size (mm x mm) |

Φ1000×700 |

Φ1000×1050 |

Φ1250×1050 |

Φ1250×1400 |

Φ1320×1500 |

Φ1500×2000 |

Φ1800×2000 |

|

Max. Feeding Size (mm) |

300 |

350 |

350 |

350 |

500 |

700 |

800 |

|

Capacity (t/h) |

30-70 |

50-90 |

70-130 |

100-180 |

130-250 |

300-550 |

600-800 |

|

Over all dimension (mm) |

2330×1660×2300 |

2370×1700×2390 |

2680×2160×2800 |

2650×2460×2800 |

3180×2720×2620 |

3959×3564×3330 |

4400×3866×4009 |

|

Motor Power (kw) |

37-45 |

45-55 |

110 |

132 |

200 |

315-400 |

630-710 |

|

Weight (t) |

12 |

15 |

17.7 |

22.4 |

27 |

50.6 |

83.2 |

| Model | PC400×300 | PC600×400 | PC800×600 | PC1000×800 |

| Rotate speed (r/min) |

1450 | 1000 | 980 | 1000 |

| Max.Feeding Size (mm) |

<200 | <250 | <300 | <400 |

| Discharge size (mm) |

<25 | <30 | <30 | <35 |

| Capacity (t/h) |

8-15 | 15-30 | 20-40 | 30-65 |

| Motor Power (kw) |

11 | 22 | 55 | 90 |

| Over all dimension (mm) |

812×982×785 | 1055×1022×1122 | 1360×1330×1020 | 3514×2230×1515 |

SMAT crushing plant is a facility designed to reduce large rocks or ores into smaller pieces for construction or industrial use. It typically includes primary, secondary, and tertiary crushers, along with screens and conveyors. Crushing plants are essential in mining, quarrying, and recycling operations, processing materials like granite, limestone, and concrete into desired sizes for further use.

Advanced technology ensures maximum output with minimal energy consumption.

Built with premium materials for extended lifespan and reduced maintenance.

Energy-saving design and minimal wear parts lower long-term expenses.

Simple access to key components for quick servicing and reduced downtime.

customized design, selection consultation

installation and commissioning, technical training

spare parts supply, remote technical support

crushing plant is a facility designed to reduce large rocks or ores into smaller pieces for construction or industrial use. It typically includes primary, secondary, and tertiary crushers, along with screens and conveyors. Crushing plants are essential in mining, quarrying, and recycling operations, processing materials like granite, limestone, and concrete into desired sizes for further use.

We provide a wide range of crushing machines, including jaw crushers, cone crushers, impact crushers, hammer crushers, and mobile crushing plants. Each type is designed for specific applications and materials.

Our machines are capable of processing various materials, including hard rock, ore, limestone, granite, basalt, recycled concrete, and more. They are suitable for mining, quarrying, and recycling operations.

The choice depends on factors like the type of material, required output size, production capacity, and operational conditions. Our team can help you select the best machine based on your specific requirements.

Yes, we offer a comprehensive range of spare parts and dedicated after-sales support to ensure your equipment operates smoothly throughout its lifespan.