The jaw crusher is a reliable machine for primary crushing, ideal for mining, construction, and recycling. It uses compressive force between a fixed and moving jaw to crush hard materials like stone and ore. With high efficiency, durability, and low maintenance, it’s perfect for demanding applications.

Feeder Opening (mm)

Capacity

Adjustment range (mm)

| Model | Cavity | Diameter of large end of crushing cone(mm) | Width of Feeding Opening | Max.feeding size(mm) | Adjusting Range of Discharge Opening(mm) | Processing capacity(t/h) | Main motor power(kw) | Machine weight(t) |

| STHP 200 | C1 | 900 | 210 | 178 | 22-38 | 160-250 | 4P 160kw | 10.1 |

| STHP 200 | C2 | 900 | 155 | 132 | 18-38 | 145-250 | 4P 160kw | 10.1 |

| STHP 200 | C3 | 900 | 130 | 110 | 14-38 | 120-250 | 4P 160kw | 10.1 |

| STHP 200 | F1 | 900 | 118 | 100 | 12-25 | 108-210 | 4P 160kw | 10.1 |

| STHP 200 | F2 | 900 | 90 | 76 | 10-25 | 81-210 | 4P 160kw | 10.1 |

| STHP 200 | F3 | 900 | 70 | 60 | 8-25 | 72-210 | 4P 160kw | 10.1 |

| STHP 300 | C1 | 1100 | 235 | 200 | 26-45 | 230-445 | 4P 220kw | 17.8 |

| STHP 300 | C2 | 1100 | 211 | 180 | 20-45 | 200-445 | 4P 220kw | 17.8 |

| STHP 300 | C3 | 1100 | 135 | 115 | 16-45 | 180-445 | 4P 220kw | 17.8 |

| STHP 300 | F1 | 1100 | 124 | 105 | 14-25 | 160-220 | 4P 220kw | 17.8 |

| STHP 300 | F2 | 1100 | 96 | 82 | 12-25 | 140-220 | 4P 220kw | 17.8 |

| STHP 300 | F3 | 1100 | 70 | 60 | 8-25 | 120-220 | 4P 220kw | 17.8 |

| STHP 400 | C1 | 1400 | 330 | 280 | 26-51 | 270-630 | 4P 315kw | 25 |

| STHP 400 | C2 | 1400 | 200 | 170 | 22-51 | 243-630 | 4P 315kw | 25 |

| STHP 400 | C3 | 1400 | 152 | 130 | 16-51 | 210-630 | 4P 315kw | 25 |

| STHP 400 | F1 | 1400 | 135 | 115 | 12-25 | 162-370 | 4P 315kw | 25 |

| STHP 400 | F2 | 1400 | 106 | 90 | 10-25 | 126-370 | 4P 315kw | 25 |

| STHP 400 | F3 | 1400 | 80 | 68 | 8-25 | 104-370 | 4P 315kw | 25 |

| STHP 500 | C1 | 1500 | 335 | 285 | 32-51 | 365-790 | 4P 400kw | 34.1 |

| STHP 500 | C2 | 1500 | 229 | 190 | 25-51 | 328-790 | 4P 400kw | 34.1 |

| STHP 500 | C3 | 1500 | 180 | 152 | 19-51 | 280-790 | 4P 400kw | 34.1 |

| STHP 500 | F1 | 1500 | 152 | 130 | 13-25 | 202-450 | 4P 400kw | 34.1 |

| STHP 500 | F2 | 1500 | 124 | 105 | 10-25 | 158-450 | 4P 400kw | 34.1 |

| STHP 500 | F3 | 1500 | 88 | 75 | 8-25 | 122-450 | 4P 400kw | 34.1 |

| STHP 800 | C1 | 2000 | 385 | 326 | 32-51 | 616-1100 | 4P 630kw | 69.2 |

| STHP 800 | C2 | 2000 | 350 | 298 | 25-51 | 522-1100 | 4P 630kw | 69.2 |

| STHP 800 | C3 | 2000 | 280 | 238 | 16-51 | 380-1100 | 4P 630kw | 69.2 |

| STHP 800 | F1 | 2000 | 160 | 136 | 13-25 | 328-730 | 4P 630kw | 69.2 |

| STHP 800 | F2 | 2000 | 120 | 102 | 10-25 | 270-370 | 4P 630kw | 69.2 |

| STHP 800 | F3 | 2000 | 90 | 77 | 8-25 | 166-730 | 4P 630kw | 69.2 |

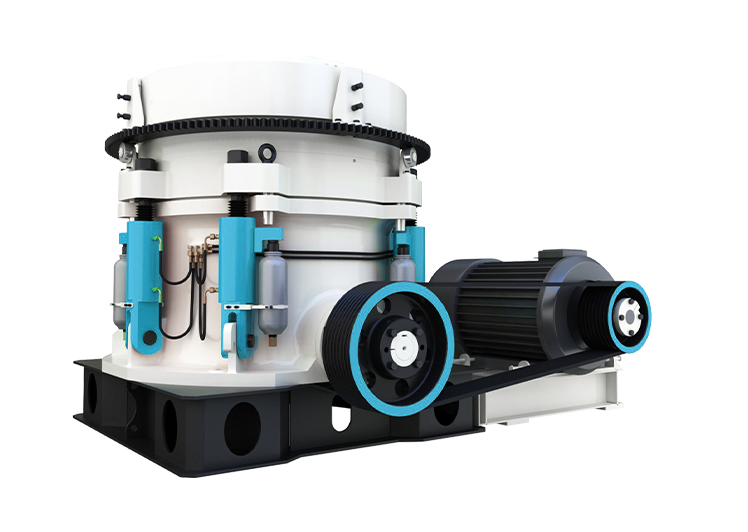

A crushing solution that combines power, precision and reliability? Our advanced multi-cylinder cone crushers are designed to deliver superior performance for the most demanding mining, quarrying and aggregate production operations. Featuring cutting-edge technology and rugged engineering, this crusher is the perfect choice for high productivity and exceptional material quality.

Why choose our multi-cylinder cone crushers?

Unrivalled crushing performance:

Our cone crushers are equipped with multiple hydraulic cylinders to ensure stable and efficient crushing, providing consistent throughput and high reduction ratios.

Precise control:

Advanced hydraulic regulation and automation systems provide precise control of the crushing process, ensuring optimum particle size and shape.

Durable and reliable:

Our cone crushers are built with high-strength materials and a robust design to withstand harsh operating conditions, ensuring long service life and short downtime.

Energy efficient:

Our crushers are optimised for low energy consumption, helping you to reduce operating costs while maintaining high productivity.

Versatility for any application:

Whether you're processing hard rock, ores or aggregates, our multi-cylinder cone crushers can accommodate a wide range of materials and applications.

Easy to maintain:

Designed with user-friendly features and easy-to-use components, maintenance and servicing is simple.

Provide regular maintenance plans and fast troubleshooting to address operational challenges.

Ensure the long-term availability of original spare parts to maintain stable equipment performance.

24/7 technical assistance via phone, email, or remote support to resolve issues promptly.

We provide a wide range of crushing machines, including jaw crushers, cone crushers, impact crushers, hammer crushers, and mobile crushing plants. Each type is designed for specific applications and materials.

Our machines are capable of processing various materials, including hard rock, ore, limestone, granite, basalt, recycled concrete, and more. They are suitable for mining, quarrying, and recycling operations.

The choice depends on factors like the type of material, required output size, production capacity, and operational conditions. Our team can help you select the best machine based on your specific requirements.

Yes, we offer a comprehensive range of spare parts and dedicated after-sales support to ensure your equipment operates smoothly throughout its lifespan.