The jaw crusher is a reliable machine for primary crushing, ideal for mining, construction, and recycling. It uses compressive force between a fixed and moving jaw to crush hard materials like stone and ore. With high efficiency, durability, and low maintenance, it’s perfect for demanding applications.

Capacity

Max. Feeding Size(mm)

| Model | Drum Diameter(mm) | Drum Length(mm) | Capacity(t/h) | Power(kw) | Overall Dimension(mm) |

| GT1015 | 1000 | 1500 | 45945 | 4 | 3000×1400×2145 |

| GT1020 | 1000 | 2000 | 15-25 | 5.5 | 3460×1400×2145 |

| GT1225 | 1200 | 2500 | 25-40 | 7.5 | 4146×1600×2680 |

| GT1530 | 1500 | 3000 | 60-80 | 11 | 4460×1900×2820 |

| GT1545 | 1500 | 4500 | 80-150 | 15 | 5960×1900×3080 |

| GT1848 | 1800 | 4800 | 150-200 | 22 | 6500×2300×4000 |

| GT1860 | 1800 | 6000 | 160-220 | 18.5 | 7700×2300×4000 |

| GT2055 | 2000 | 5500 | 200-260 | 30 | 7500×2500×4000 |

| GT2580 | 2500 | 8000 | 300-600 | 22×2 | 12250×2980×6200 |

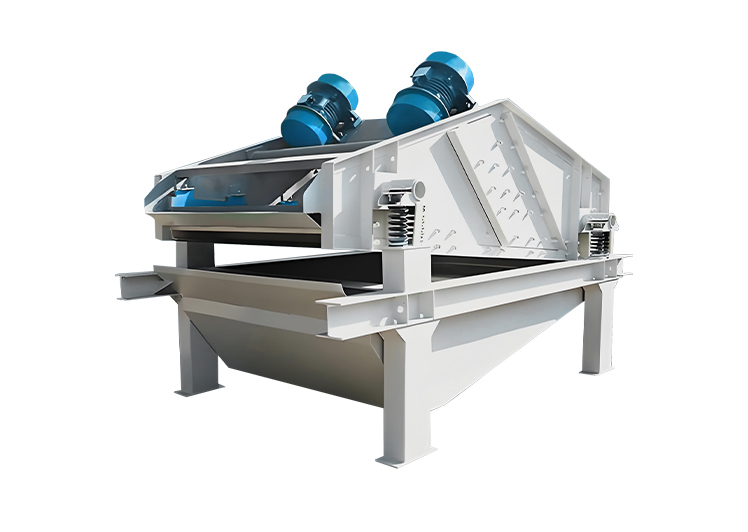

Are you struggling with inefficient water removal, high moisture content, or material loss in your mining, aggregate, or recycling operations? Our advanced Dewatering Screen is the ultimate solution for efficient solid-liquid separation, ensuring dry, manageable materials and maximum productivity. Designed for durability, reliability, and performance, our dewatering screen is the perfect addition to your processing line.

Why Choose Our Dewatering Screen?

Superior Dewatering Efficiency:

Our screen uses high-frequency vibration and advanced filtration technology to remove water effectively, delivering dry, stackable materials with minimal moisture content.

Versatility for Multiple Applications:

Ideal for sand, gravel, coal, tailings, and slurry dewatering, our machine adapts to a wide range of industries, including mining, aggregates, and recycling.

Durable and Reliable Design:

Built with high-quality materials and robust engineering, our dewatering screen is designed to withstand harsh operating conditions, ensuring long-lasting performance.

Low Maintenance and Operational Costs:

With a simple design and easy-to-access components, maintenance is quick and hassle-free, reducing downtime and saving you money.

Compact and Space-Saving:

Our dewatering screen is designed for easy integration into existing processing lines, saving valuable space in your facility.

Environmentally Friendly:

By efficiently recycling water and reducing waste, our dewatering screen helps you achieve sustainable and eco-friendly operations.

Customizable Solutions:

We offer tailored configurations to meet your specific dewatering needs, ensuring optimal performance for your unique applications.

Provide regular maintenance plans and fast troubleshooting to address operational challenges.

Ensure the long-term availability of original spare parts to maintain stable equipment performance.

24/7 technical assistance via phone, email, or remote support to resolve issues promptly.

We provide a wide range of crushing machines, including jaw crushers, cone crushers, impact crushers, hammer crushers, and mobile crushing plants. Each type is designed for specific applications and materials.

Our machines are capable of processing various materials, including hard rock, ore, limestone, granite, basalt, recycled concrete, and more. They are suitable for mining, quarrying, and recycling operations.

The choice depends on factors like the type of material, required output size, production capacity, and operational conditions. Our team can help you select the best machine based on your specific requirements.

Yes, we offer a comprehensive range of spare parts and dedicated after-sales support to ensure your equipment operates smoothly throughout its lifespan.