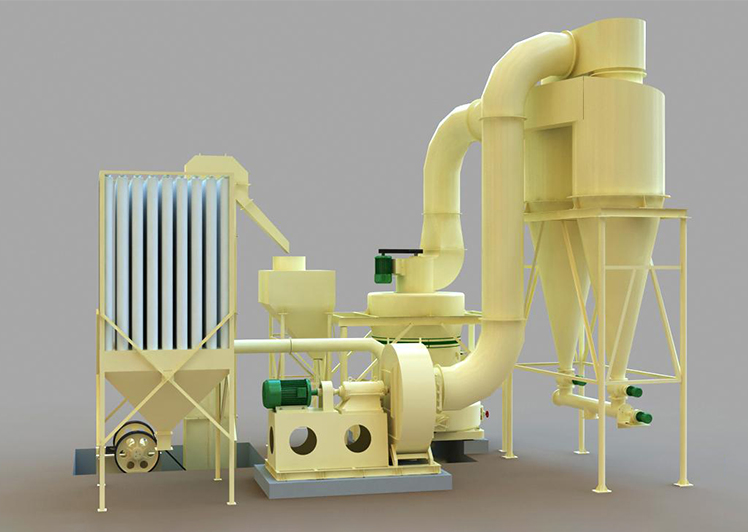

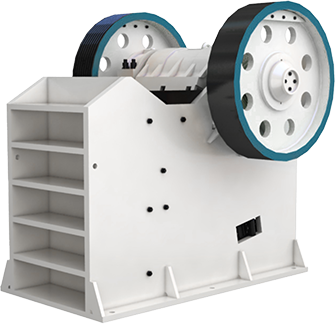

SMAT is a leading global manufacturer of mining machinery and industrial equipment, specializing in the research, development, production and sales of mining crushing machinery, grinding machinery, mineral processing equipment, ball press equipment and generator sets. With efficient, durable and energy-saving equipment as its core competence, the company is committed to providing customers with comprehensive mining, material processing and industrial solutions.

SMAT’s products are widely used in mining, metallurgy, construction, chemical and energy industries, serving many countries and regions around the world. With excellent performance and reliable service, we have established long-term cooperative relationships with many famous enterprises.

company was established in

Plant Area

Service Customer

Production lines

By offering comprehensive and reliable services, SMAT is dedicated to supporting clients at every stage of their operations and ensuring long-term success.

Provide expert technical advice to understand customer requirements and recommend the most suitable equipment solutions.

Offer tailored production line designs, including configurations for crushing, grinding, mineral processing, and briquetting equipment.

Arrange product performance tests or virtual demonstrations to help clients better understand the functionality and benefits.

Deliver customized equipment solutions based on specific client needs, including size, materials, and technical configurations.

Deploy experienced technicians for on-site equipment installation to ensure proper setup.

Conduct equipment commissioning and provide operator training, ensuring seamless production startup and smooth operation.

Provide regular maintenance plans and fast troubleshooting to address operational challenges.

Ensure the long-term availability of original spare parts to maintain stable equipment performance.

24/7 technical assistance via phone, email, or remote support to resolve issues promptly.

Deliver end-to-end project solutions, from design and manufacturing to installation and commissioning, allowing clients to start production immediately.

Offer professional training programs for customers, covering equipment operation, maintenance, and production optimization.

Provide long-term technical consultation to help customers maximize efficiency and productivity.

Establish service hubs or partnerships in key regions to ensure quick response times and reliable support for international clients.

Provide eco-friendly and energy-efficient solutions to help customers reduce energy consumption and minimize environmental impact.

A global service team ensures rapid resolution of equipment issues.

Offer equipment upgrades to extend operational lifespan.

A team of seasoned professionals ensures standardized and efficient services.

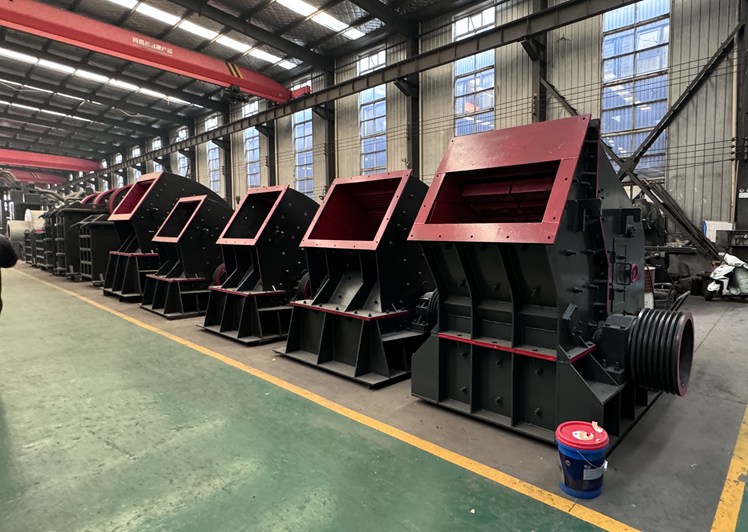

With our advanced production facilities and automated systems, we manufacture over 5,000 units of crushing machinery annually, tailored to meet the rigorous demands of the mining, quarrying, and construction industries worldwide.

Our facility utilizes advanced laser cutting machines and CNC plasma cutters to precisely shape high-strength steel and other materials, ensuring the durability and performance of our crushing machines.

Key components, such as crushing chambers and rotors, are manufactured using 5-axis CNC machining centers, achieving micron-level precision for enhanced efficiency and reliability.

We employ automated robotic welding systems to ensure consistent, high-strength welds, followed by precision assembly lines that guarantee each crusher meets strict structural and performance standards.

Our facility features advanced heat treatment furnaces to improve the hardness and durability of key components, such as crusher jaws and liners, ensuring long-lasting performance.

All crushing machinery undergoes automatic sandblasting and powder coating to protect against harsh working conditions, ensuring durability and corrosion resistance.

Each crushing machine is meticulously assembled and rigorously tested using dynamic balance testing machines and vibration analyzers to ensure optimal performance and stability before delivery.

Exhibition

Exhibition

Exhibition

Exhibition

Exhibition

Exhibition