The client, a well-established construction company in the Philippines, was seeking a high-capacity, efficient, and reliable mobile crushing solution for their aggregate production needs. After extensive discussions and technical evaluations, SMAT provided a customized 100-ton-per-hour mobile crushing line tailored to the client’s project requirements.

• Location: Italy

• Material: Coal

• Capacity: 5 tons per hour

• Application: Coal, Charcoal, Power Solution

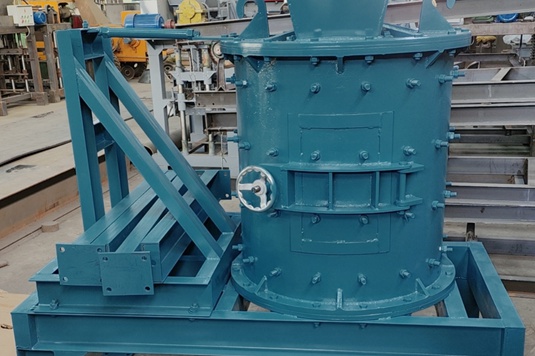

Model: Double-stage hammer crusher

Function: Crushing raw coal into fine particles (<3mm) for optimal briquetting results.

Advantages: high crushing rate, low energy consumption, low dust generation.

Function: Compact coal powder into oval or pillow-shaped balls (30-50mm).

Advantages:

High pressure (up to 120 MPa) ensures dense balls with low breakage rate.

Adjustable mold for customizable shape/size.

Automatic pressure regulation for energy saving.

Function: Connect all equipment for continuous operation.

Features:

Stainless steel structure for durability.

Variable speed control for synchronized workflow.