We recently supplied a mining company in Mexico with a highly efficient mineral crushing and grinding line designed to process raw ore into fine powder for further metallurgical or industrial applications. The complete system includes primary crusher, secondary crusher and ball mill, ensuring optimal particle size reduction and processing efficiency.

• Location: Mexico

• Material: Stone

Model: jaw crusher

Function: break down large raw ore (up to 500 mm) into smaller pieces (50-100 mm).

Advantages:

High crushing rate and high output

Rugged structure for heavy-duty use

Hydraulic adjustment for easy maintenance

Function: further reduce the ore size (from 50-100 mm to 10-30 mm) for finer grinding.

Advantages:

Precise particle size control

Energy-saving operation

Hydraulic overload protection to ensure safety

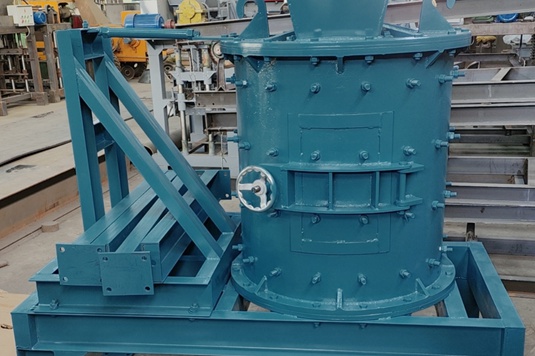

Model: dry and wet ball mill (customized according to ore type)

Function: grind the crushed ore into fine powder (usually 50-200 mesh).

Advantages:

High grinding efficiency and low energy consumption

Adjustable speed to meet different fineness requirements

Wear-resistant lining for extended service life